charpy impact testing of steel|charpy impact tester pdf : department Store impact testing of mild steel, the Charpy Impact Test can provide information on how much energy a specimen such as mild steel can absorb under an impact scenario. In this context, the following sections will present information on: 1) impact testing; 2) effect of .

Resultado da An entity of undefined identity. A being of one and the other, who knows no bounds. Aernas has once again fallen into an unfathomable danger. Even though a small droplet can create waves in order, one can also find order within the turbulent chaos. The alpha of Chaos. And the omega of .

{plog:ftitle_list}

webGarden Motel, Franca: veja dicas e avaliações dos hóspedes, fotos e promoções para Garden Motel no Tripadvisor.

undersized charpy impact test

This makes Charpy testing a popular choice for assessing the toughness of metals like steel, as well as polymers, composites, and ceramics. Here’s how the process works: The test specimen, typically 55 mm long and 10 mm square with a 2 mm deep V-notch, is positioned horizontally .

notched charpy impact test

According to ASTM A370, the standard specimen size for Charpy impact testing is 10 mm × 10 mm × 55 mm. Subsize specimen sizes are: 10 mm × 7.5 mm × 55 mm, 10 mm × 6.7 mm × 55 mm, 10 mm × 5 mm × 55 mm, 10 mm × 3.3 mm × 55 mm, 10 mm × 2.5 mm × 55 mm. Details of specimens as per ASTM A370 (Standard Test Method and Definitions for Mechanical Testing of Steel Products).The ISO 148-1 standard specifies the Charpy (U-notch and V-notch) impact test on metals for determination of the impact strength. The impact strength of a material is an important characteristic for applications in pipeline construction .

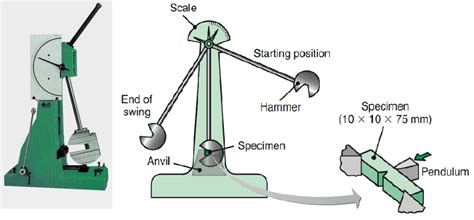

Figure 2-1: Charpy impact tester, sample positioned in anvil and general testing results. This test has been used almost exclusively with body-centered-cubic (bcc) crystalline materials. These .In this investigation, we performed instrumented Charpy tests in order to characterize the impact properties of three steels, used by NIST for the production of Charpy reference specimens .impact testing of mild steel, the Charpy Impact Test can provide information on how much energy a specimen such as mild steel can absorb under an impact scenario. In this context, the following sections will present information on: 1) impact testing; 2) effect of .

According to current Charpy test standards (ASTM E23-12c and ISO 148-1:2009), absorbed energy . the production of reference Charpy specimens for the indirect verification of impact testing machines in accordance with ASTM E23-12c: two quenched and tempered 4340 steels (with different mechanical properties . steel is an 18 Ni maraging steel .

Impact test. Measures the ability of a material to absorb a sudden application of a load without breaking. The Charpy test is a commonly used impact test. Lateral expansion. The lateral change in dimension of a Charpy impact specimen due to fracture. The dimension measured is the width opposite the v-notch (see Fig. 1-3).Understanding the critical importance of Charpy Impact Testing sets the stage for delving into its step-by-step procedure and intricacies – an insightful journey that demystifies this essential method for assessing material toughness. Step-by-step Procedure of a Charpy Impact Test. Performing a Charpy impact test involves several important steps.

charpy impact testing

charpy impact tester pdf

compression tester lq4

To determine the material resistance to impact from a swinging pendulum. Apparatus Required. Charpy testing machine, a rod of mild steel and a rod of carbonate steel. Charpy Test Specimens. Charpy test specimens normally measure 55x10x10mm and have a notch machined across one of the larger faces. The notches may be :

Service Steel Warehouse: Your Full-Service Steel Supplier. Founded in 1965 in Houston, Texas, Service Steel Warehouse is a nationwide full-service steel supplier distributing structural carbon steel and providing steel services such as Charpy impact testing.Not only do we offer a full stack of steel services to customize your order to exactly meet your needs, but we also stock .

Charpy impact testing (also known as the Charpy v-notch test) is a high strain rate testing standard that determines the amount of energy absorbed by a material during a fault (Kim et al., 2015).For impact testing of mild steel, the Charpy Impact Test can provide information on how much energy a specimen such as mild steel can absorb under an impact scenario. In this context, the following sections will present information on: 1) impact testing; 2) effect of temperature; 3) 17-4PH test material; 4) impact toughness of 17-4PH in H900 .

Charpy impact test and three-point bending test on 32 mm and 50 mm thick Q690 high-strength steel were carried out according to the environmental features of plateau low temperature to assess the .This page introduces the Charpy impact test principle and methods; as well as evaluation methods, test piece standards, differences from the Izod impact strength test, and methods for measurement of the fracture surface. The 3D Solutions Library operated by KEYENCE introduces examples of shape measurement problems and the latest solutions for various industries, .

Test criteria for Charpy V-notch impact testing usually involve (i) a minimum impact energy value, (ii) shear appearance of fractured test bars expressed in percent, and (iii) lateral expansion. For steels, the minimum acceptable values generally specified for these three evaluation methods are 20 J, 50 % shear, and 1.3 mm respectively. Charpy impact testing determines the impact energy of materials. The test procedure, the application of charpy testing, factors affecting impact energy, the ductile to brittle transition are all covered.ASTM A370 is one of the most broadly recognized and encompassing standards for measuring the tensile strength of metals.This guide is designed to introduce you to the basic elements of an ASTM A370 tensile test and provide an overview of the testing equipment, software, and specimens needed. In addition to tension tests, the standard also outlines charpy impact, .

The ASTM E23 standard describes notched bar impact testing of metals according to Charpy and Izod.For the test, a notched metal specimen is broken in half using a pendulum hammer. The ASTM E23 standard describes the requirements for specimens, for the performance of the test, for result reports and for testing machines, i.e., pendulum impact testers at ambient .completed impact tensile testing results at -20oF conditions for dual-marked 304/304L and 316/316L stainless steel material specimens (hereafter referred to as 304L and 316L, respectively). Recently completed welded material impact testing at -20 oF, room, 300 oF, and 600 oF is also reported. Utilizing a drop-weight impact test machine and 1/4 .Keywords: Impact test analysis, steel and aluminum, metal materials This article is licensed under CC BY-SA 4.0 INTRODUCTION . Chaerul Umam Wardani et al in 2009, analyzed the impact testing of the Izod and Charpy methods using ST37 aluminum and steel test specimens. In the Charpy test, a sample of .

Experiment 7: Charpy Impact Test Name: Om Prabhu Roll Number: 19D170018 Objectives: . For mild steel, impact strength is maximum at room temperature. ii)At lower temperatures, the material is more brittle and the fracture surface has a shiny, crys-talline appearance. There is negligible distortion at the sides. The measured parameters were used to simulate the Charpy impact test of armour steel specimen and reliable results were obtained. Based on J-C model, Madhusudhan [8] and Pervaiz [9] succeeded in realizing modeling and simulations of Charpy impact tests of maraging steel 300 and 6061 aluminum alloy, respectively.The Charpy V-notch-CVN impact test also known as the Charpy V- notch test, is a standard test used to measure the impact energy (also referred to as notch toughness) absorbed by a material during fracture. The notch provides a point of stress concentration within the specimen and improves the reproducibility of the results.

Impact testing is required for many critical applications in the construction, machinery and equipment, defense, and energy markets. Charpy testing provides data needed to ensure the quality and reliability of structural steel products. Over 1,000 machines per year are evaluated for conformance with

Charpy impact test standards. ASTM E23, ASTM D6110, ASTM A370, ASTM D256. ISO 13479, ISO 148-1. EN 10045-1, EN ISO 179-1 Izod impact testing. While Charpy impact testing is widespread for metals, Izod impact testing is more often used for plastics and other softer materials. In Izod testing, the notched specimen is positioned vertically instead .

The chemical composition of the test steel (SA508 Gr.4N) . The temperature dependence of the Charpy impact energy of the SA508Gr.4N steel is shown in Fig. 4. The Charpy energy curves can be . 1.1 This specification covers the procedure for Charpy V-notch testing of structural steel and contains two frequencies of testing. The impact properties of steel can vary within the same heat and piece, be it as-rolled, control-rolled, or heat treated. The purchaser should, therefore, be aware that testing of one plate, bar, or shape does not provide .

The Charpy test results are affected by many factors, such as the state of the specimen (size, notch type, notch depth, etc.), the state of the impact testing machine (stiffness, hammer radius . Typically these steels are exempt from impact testing for minimum design temperatures -29°C (-20°F) per ASME B31.3 for thicknesses up to 12.7 mm (0.5 in). It has been found that the cause of the unexpected low toughness was a combination of changes in the chemical composition of the steel due to changes in the steel making practices.The Charpy-V test for characterising notch toughness is described. The qualitative nature of the test, outline procedures and test analysis are described. . There are two main forms of impact test, the Izod and the Charpy test. . see, for example the impact test requirements of EN 10028 Part 2 Steel for Pressure Purposes.

Charpy Impact testing is used in studying material toughness and most importantly it indicates a material ability to absorb energy and plastically deform without fracturing. In this study, three stainless steel specimens at different temperature -78°C, 80°C and 7°C respectively were utilized.

charpy impact test time

charpy impact test temperature

webMGMT "Loss Of Life". I Dont Know How But They Found Me "GLOOM DIVISION". Amaranthe "The Catalyst". Jazmin Bean "Traumatic Livelihood". Allie X "Girl With No .

charpy impact testing of steel|charpy impact tester pdf